- All-in-one solution

- No moving parts

- No adjustments

- Heavier loads

- Discreet flush finish

- 20 second installation

Having designed a plasterboard fixing capable of withstanding particularly high load factors in SHEAR, we thought the next logical step would be to design a picture hook to work in perfect harmony.

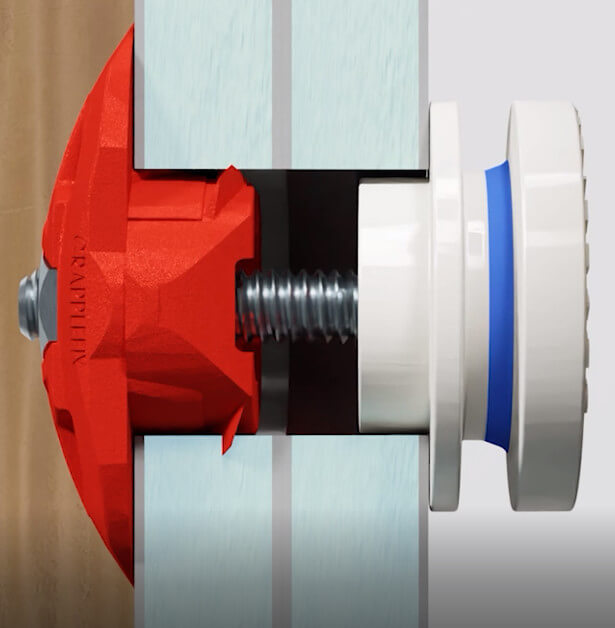

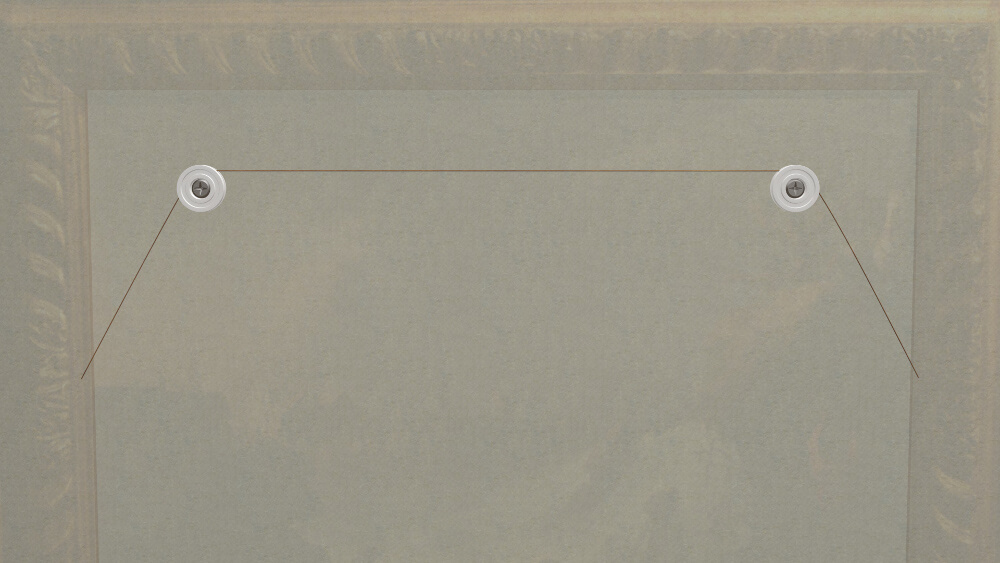

These hooks (roundels) are particularly effective when used as horizontally opposed pairs for hanging large, heavy items such as mirrors. Conventional picture hooks are not designed to work in pairs that generate lateral forces causing them to skew from their vertical position, which can be problematic. The Grapplefix picture hook installs directly into the hole in the plasterboard as there is no obscuring front flange from the fixing itself. This is highly advantageous due to the extended surface area in direct contact with the plasterboard, which produces a beneficial sandwiching effect (structural lamination) and also provides the opportunity to utilise a locating ring to assist with installation and enhance performance. Orientation issues are permanently removed. Unlike conventional hooks, the central fixing bolt resides underneath the picture wire, which acts as a further failsafe.

Our picture hook has some distinct advantages over conventional (hook-shaped) hooks, summarised below:

The hook works equally well for smaller, lighter loads, but when hanging significant loads (above 10 Kg), we recommend using a 7 x 7 (49 individual strands) 1.5 mm steel wire.

The breaking strain of this type of wire is usually around 140 Kg (check the specification prior to installation). It is made up of 7 bundles, each containing 7 strands. This configuration gives the wire the required flexibility.

Other wire configurations such as 7 x 19 are even more flexible (therefore allowing for increased diameters) and a 2 mm, 7 x 19 steel wire would give a breaking strain up to 230 Kg where extra safety multiples are required. Again, check the specification carefully prior to installation.

Please note that the picture hook slot is limited to wires (including any additional coating) of 3 mm (maximum) diameter.

Optimally, the ends of the wire should be as close to vertical as possible (with the two hooks positioned horizontally apart as far as possible), as this represents the configuration with the lowest resulting tension in the wire. However, this may not always be practical and is an optional configuration. The ends of the wire may diverge (as shown below – the less the better), be almost vertical (preferred) or even converge if required.

Yes, the Grapplefix picture hook is heavy duty, with a highest recommended load of 50Kg for single 12.5 mm thickness plasterboard.

Yes. The picture hook and fixing have been independently tested by Building Research Establishment to British Standard BS 5234-2.

Grapplefix has created the strongest picture hook for plasterboard on the market today.

Yes, this is one of the key design strengths of our picture hook. The hooks will not rotate inwards under load unlike traditional hooks that rip out under lateral forces when more than one hook is required e.g. for hanging a heavier or wider item. Additionally the bolts reside below the picture wire for additional security.

Yes. The hooks with the shallower locating rings (2 in each pack) can be used on 9.5 mm plasterboard, which can be present in some houses, usually upstairs. These can also be used on thicker boards.

Yes. Except for 9.5 mm plasterboards, double thickness boards will require longer bolts.

Due to the innovative design, double thickness boards significantly increase performance from 103 Kg failure limit to 195 Kg failure limit on double 12.5 mm boards. Maximum recommended limits are half of these limits.

A 16 mm bit or preferably a hole saw is required

The red M5 short back plate fixing. The picture hook pack contains 4 picture hooks, 4 red fixings and 4 M5 bolts, plus a universal applicator tool that can be used for all Grapplefix fixings.

Yes, the fixing can be installed into cavities down to 20 mm.

Yes. Unlike other fixings that rely on front plugs, Grapplefix fixings do not occlude the drilled hole in the tile allowing for easy hook insertion. Installation takes seconds as there are no alignment issues and no moving parts.

No, picture hooks can currently only be purchased in a kit. They are specifically designed to be used with a Grapplefix fixing.

The red fixing can only be used in plasterboard. Fixings for use in other substrates will be released shortly, which can then be used with the picture hook depending on the depth of the panel. Minimum panel thickness would be 9 mm.

Hanging packs will be available shortly.